Offshore survey on a rig which lead to replacing a set of units with upgraded attenuators which greatly improved the noise level from the engines.

Veotec has safety-certified personnel able to carry out onsite surveys. A full condition survey of existing equipment can be carried out with reference to ensuring equipment is functioning correctly and still meets the client’s requirements.

Suggested improvements can also be made to improve the efficiency, maintenance and running costs of equipment.

For example by upgrading a gas turbine intake we can improve significantly the protection of the turbine, extending the interval between costly services and reducing downtime.

Often by talking first hand to the operatives in the field, particular problems can be identified and resolved.

We can then prepare a detailed report of our findings and recommendations.

This enables us to design equipment which we know will fit into the available space and identify potential installation problems.

The cost of this service can be offset against future orders as a result of this work. We can also then supervise the installation of equipment we have manufactured to ensure correct operation and help with commissioning.

Pressure plotting of ductwork

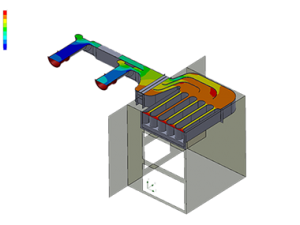

Computational Fluid Dynamics (CFD)

As part of its ongoing commitment to product development and customer service Veotec has an in house CFD capability.

This means that not only can we prove our existing products meet the most demanding of specifications but also test new ideas and designs.

We have, using this capability, designed complicated ductwork and intake systems and proven they will perform as required, measuring airflow patterns and resistance figures. This can then be adjusted quickly and the new results seen.

Shock Testing

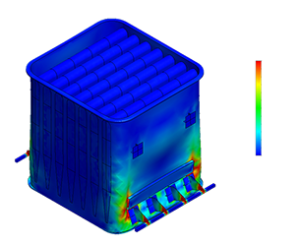

Structural Analysis (FEA)

When designing a new intake system or retrofitting an upgrade to an existing system, Veotec can offer the in house ability to carry out structural analysis.

This can be used to calculate load bearings or for shock test analysis, for example when designing a system to be used by a navy warship.

Veotec is committed to using the latest technology to improve its service to its customers and for product development.